Component Inspection and Quality Control

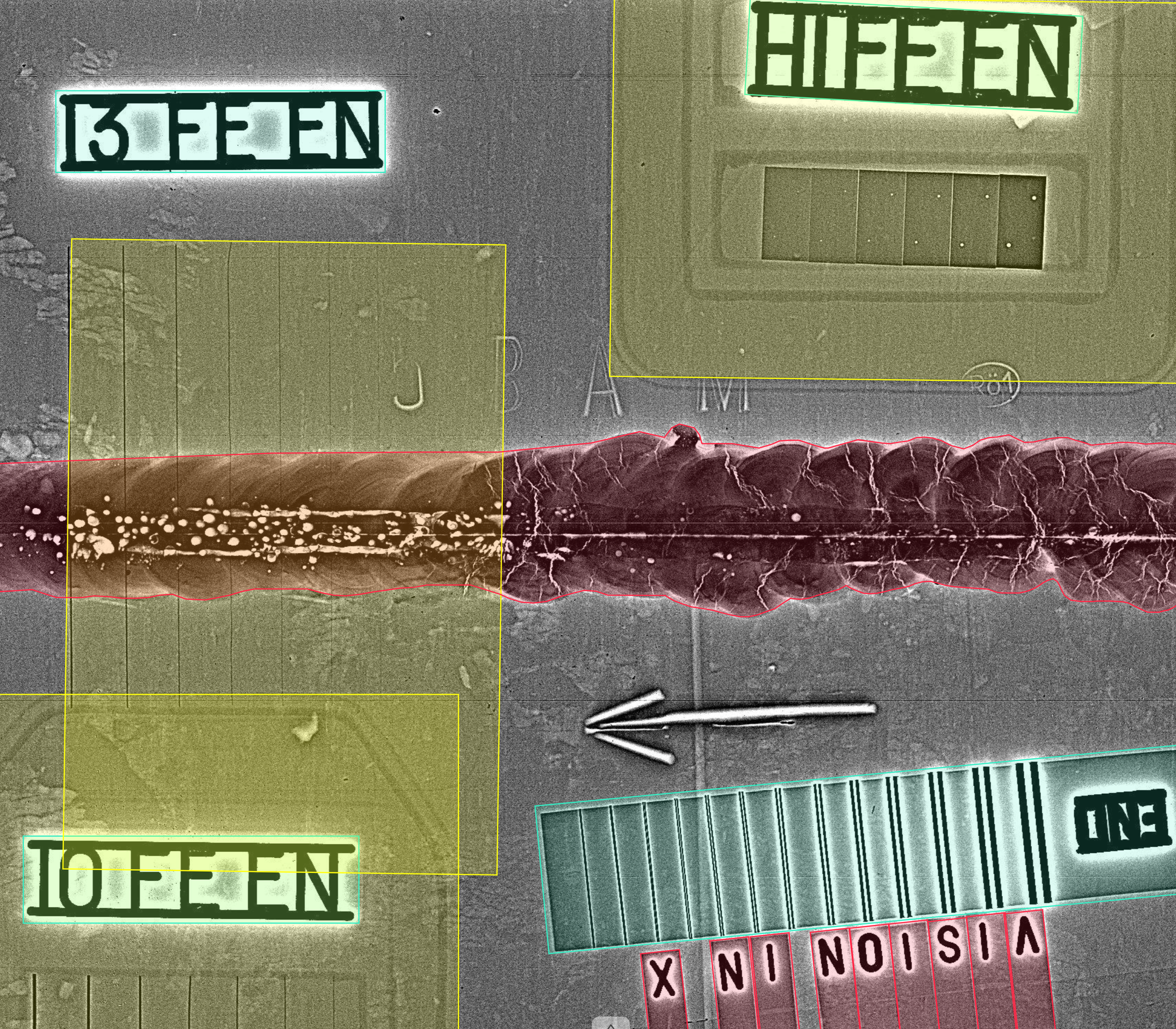

We annotate manufacturing components and assemblies to enhance automated inspection systems. Some of our key areas include:

- PCB Component Detection

- Automobile Parts Quality Control

- Bottling Line Inspection

- Textile Defect Analysis

- Welding Inspection

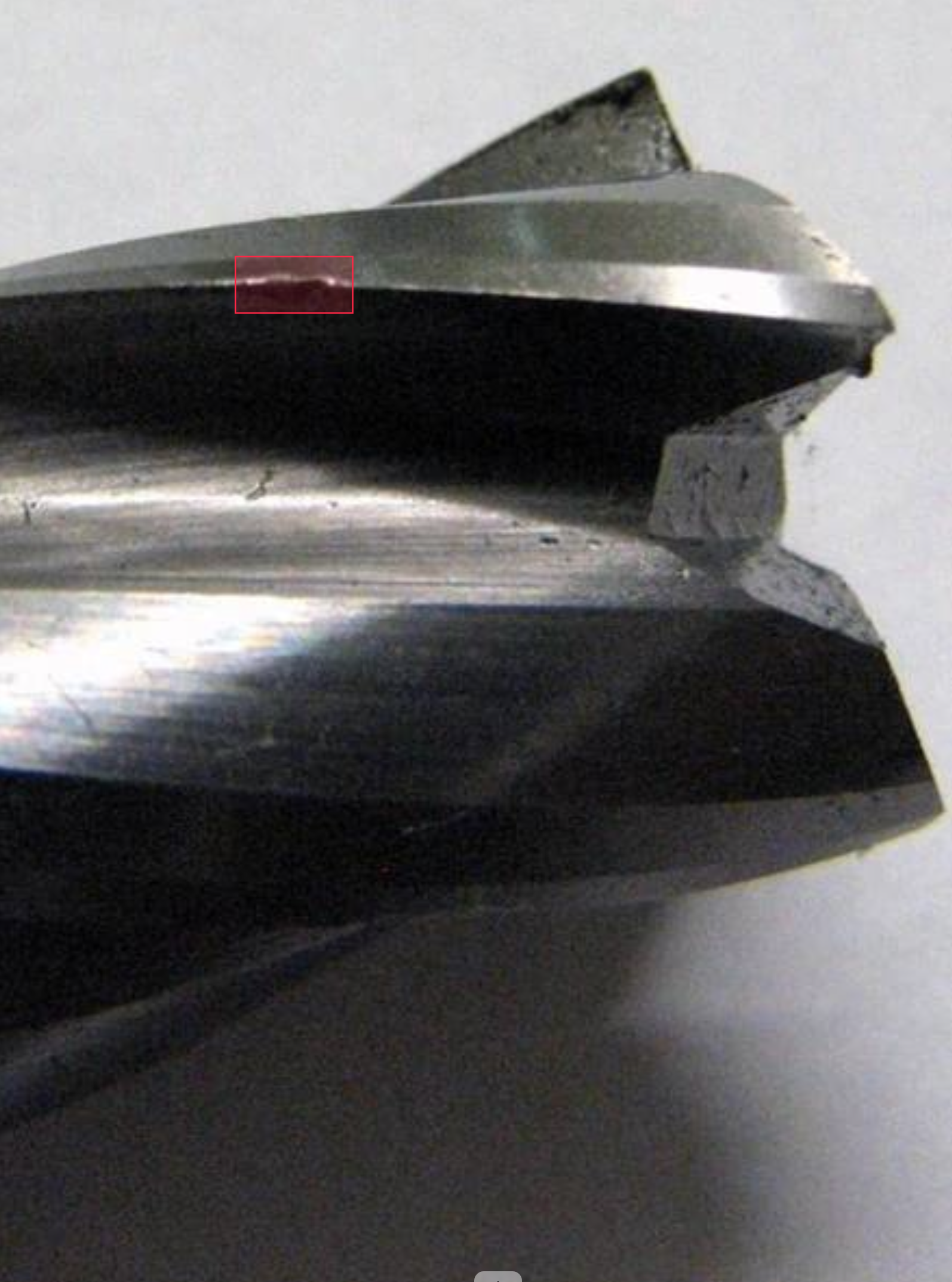

Predictive Maintenance

Enhance equipment reliability through annotated data.

- Industrial Equipment Monitoring

- Vibration Pattern Analysis

- Wear-and-Tear Detection

- Thermal Imaging Analysis

Inventory Management and Logistics

Data annotation plays a critical role in tracking and managing inventory flow in manufacturing.

- Warehouse Object Recognition

- Conveyor Belt Item Tracking

- Inventory Barcode Detection

- Supply Chain Visualization

Worker Safety and Compliance

Use data annotation to improve worker safety and regulatory compliance.

- PPE Detection

- Hazardous Area Monitoring

- Ergonomics Analysis

- Incident Reporting Systems